Anticorrosion Protection Unit

The Corrosion Protection Team has a highly specialised corrosion laboratory that carries out tests on mortars, adhesives, paints, varnishes and manufactured coatings designed to protect metals and reinforced concrete against corrosion. The laboratory is accredited by PCA (Polish Centre for Accreditation) no. AB 1424. The full scope of accreditation can be found HERE.

At the request of our customers, we perform corrosion tests, including accelerated corrosion tests, tests of corrosion resistance of products, tests of resistance of coatings to environmental conditions, as well as tests necessary to issue a National Technical Assessment, PSE Technical Recommendation or in accordance with the requirements of NORSOK (Coating procedure CPT test), PKP, etc.

In addition to laboratory testing, we also perform field testing and provide coating inspector supervision services, consulting services in the design of corrosion protection, technical specifications or quality assurance programs (PZJ).

We solve the most complicated corrosion problems within the scope of expert opinions and technical opinions of both engineering structures and buildings, tanks, devices, pillars, chimneys, etc.

For over 20 years we have been providing training in the proper design, supervision and execution of corrosion protection of steel and reinforced concrete structures.

CORROSION TESTING, PAINT TESTING, COATING TESTING, CORROSION CONSULTING, CORROSION EXPERTISE, COATING INSPECTION, CORROSION AND INSPECTION TRAINING

-

Testing of liquid paints

-

Corrosion tests of coatings for metal substrates

-

Testing of coatings, hydrophobic impregnates and mortars applied to concrete substrates

-

Performing field tests

-

Inspectorate supervision

-

Technical expertises

-

Development and verification of documents

-

Technical consulting on corrosion, corrosion problems, corrosion protection coatings

-

Conducting R&D projects

-

Training in corrosion, surface preparation before coating, coating application, training in anti-corrosion standards, inspector training

Testing of liquid paints

In the field of testing paints and varnishes in liquid form we perform, among others:

- Determination of density, part 1: pycnometer method acc. to PN-EN ISO 2811-1:2016-04

- Determination of density, part 2: immersed body method acc. to PN PN-EN ISO 2811-2:2011

- Determination of flow time by use of flow cups acc. to PN-EN ISO 2431:2019-07

- Determination of non-volatile-matter content acc. to PN-EN ISO 3251:2019-07

- Testing of paint appearance: checking for skinning, phase separation, presence of foreign matter, consistency, sedimentation acc. to PN-EN ISO 1513:2010, PN-EN ISO 12944-7:2018-01

- Drying test acc. to PN-EN ISO 9117-1:2009, PN-EN ISO 9117-3:2010

- Visual comparison of colour of paints acc. to PN-EN ISO 3668:2020-08

- FTIR analysis acc. to PN-EN 1767:2008

Corrosion tests of coatings for metal substrates

Accelerated corrosion testing of coatings applied to metal substrates

In terms of accelerated corrosion testing, we perform:

- Corrosion tests in artificial atmospheres — Salt spray tests– NSS test acc. to PN-EN ISO 9227:2017-06

- Coating testing in the UV chamber – Methods of exposure to laboratory light sources — Part 3: Fluorescent UV lamps acc. to PN-EN ISO 16474-3:2021-06

- Coating tests in the humidity chamber - Determination of resistance to humidity — Part 1: Condensation (single-sided exposure) acc. to PN-EN ISO 6270-1:2018-02

- Coating tests in the variable temperature chamber according to the IBDiM procedure TW-34/98

- Cyclic aging test acc. to PN-EN ISO 12944-6:2018-03, Anex B

- Determination of resistance to liquids — Part 1: Immersion in liquids other than water acc. to PN-EN ISO 2812-1:2018-01

- Determination of resistance to liquids — Part 2: Water immersion method acc. to PN-EN ISO 2812-2:2019-01

- Determination of resistance to cathodic disbonding of coatings exposed to sea water acc. to PN-EN ISO 15711:2006, meth. A

- corrosion resistance test of steel structures acc. to PN-EN ISO 12944-6:2018-03 /Ap1:2018-10

- corrosion resistance testing of offshore and similar steel structures acc. to PN-EN ISO 12944-9:2018-03/Anex B

Mechanical testing of coatings applied to metal substrates

In the field of mechanical testing of coatings we perform, among other things:

- Pull-off test for adhesion acc. to PN-EN ISO 4624:2016-05 and PN-EN ISO 16276-1:2008

- Assessment of, and acceptance criteria for, the adhesion/cohesion (fracture strength) of a coating — Part 2: Cross-cut testing and X-cut testing acc. to PN-EN ISO 16276-2:2008

- Determination of film thickness acc. to PN-EN ISO 2808:2020-01

- Determination of film thickness of thermal sprayed coatings acc. to PN-EN ISO 2063-1, PN-EN ISO 2063-2

- Determination of film hardness by pencil test acc. to PN-EN ISO 15184:2020-07

- Bend test acc. to PN-EN ISO 6860:2006

- Rapid-deformation (impact resistance) tests — Part 1: Falling-weight test, large-area indenter acc. to PN-EN ISO 6272-1:2011

- Determination of mar resistance acc. to PN-EN ISO 12137:2012

- Determination of resistance to abrasion — Part 1: Method with abrasive-paper covered wheels and rotating test specimen acc. to PN-EN ISO 7784-1:2016-05

- Cupping test acc. to PN-EN ISO 1520:2007

Other coating tests and evaluation of coatings applied to metal substrates

Other coating tests include:

- determination of gloss value at 20°, 60° and 85° acc. to PN-EN ISO 2813:2014

- electrochemical impedance spectroscopy (EIS) on coated and uncoated metallic specimens acc. to PN-EN ISO 16773-1:2016

- assessing the deterioration of coatings by determining the amount and extent of damage and the intensity of uniform changes in appearance: ocena zniszczenia powłok wg PN-EN ISO 4628-1:2016

- assessment of degree of blistering acc. to PN-EN ISO 4628-2:2016

- assessment of degree of rusting acc. to PN-EN ISO 4628-3:2016

- assessment of degree of cracking acc. to PN-EN ISO 4628-4:2016

- assessment of degree of flaking acc. to PN-EN ISO 4628-5:2016

- assessment of degree of chalking by tape method acc. to PN-EN ISO 4628-6:2012

- assessment of degree of delamination and corrosion around a scribe or other artificial defect acc. to PN-EN ISO 4628-8:2013

- assessment of porosity in a dry film acc. to PN-EN ISO 29601:2011

- measurement of, and acceptance criteria for, the thickness of dry films on rough surfaces acc. to PN ISO 19840:2009

- determination of coating type - FTIR analysis acc. to PN-EN 1767:2008

- determination of resistance to cathodic disbonding of coatings exposed to sea water acc. to PN-EN ISO 15711:2006

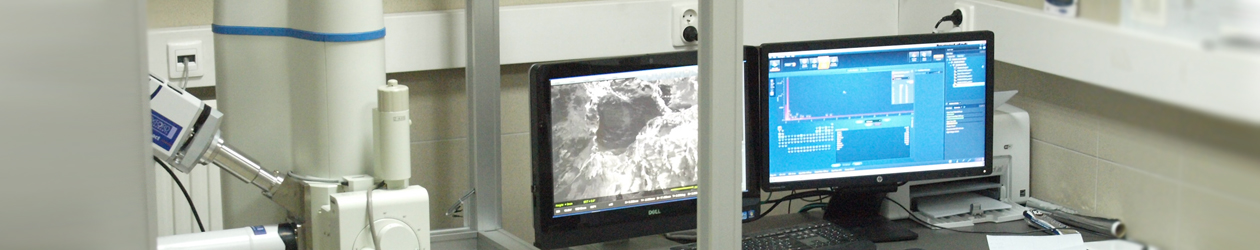

- morphology of the anticorrosion system including determination of the size of anticorrosion pigments, analysis by scanning microscopy acc. to PN-EN ISO 2808:2008 met. 6A

- determination of the presence of chromium VI and lead compounds using a scanning microscope - non-standard method

- colour measurement acc. to PN-EN 7724-2:2003 and PN-EN 7724-3:2003

Testing of metal surfaces prior to application of coatings

In the field of testing of metal surfaces prior to application of coatings, we perform, among others.:

visual inspection of surface cleanliness - determination of degree of corrosion and degree of preparation of unprotected steel substrates and steel substrates after:

- complete removal of previously applied coatings acc. to PN-EN ISO 8501-1:2008

- local removal of these coatings acc. to PN-EN ISO 8501-2:2008

- determine the degree of preparation of welds, sharp edges and other areas with surface defects acc. to PN-EN ISO 8501-3:2008

- determination of metal wall thickness by ultrasonic method acc. to PN-EN ISO 2808:2020

- evaluation of the presence of greasy impurities acc. to ASTM F222, PN-70/H-97052

- tests to assess surface cleanliness:

- extraction of water soluble contaminants for analysis (Bresle method) acc. to PN-EN ISO 8502-6:2020

- assessment of dust on steel surfaces prepared for painting (pressure-sensitive tape method) acc. to PN-EN ISO 8502-3:2017

- estimation of the probability of condensation prior to paint application acc. to PN-EN ISO 8502-4 :2017

- field method for the conductometric determination of water-soluble salts acc. to PN-EN ISO 8502-9:2021-03

- a test to determine the surface roughness characteristics of steel substrates after abrasive blasting:

- method for the grading of surface profile of abrasive blast-cleaned steel — Comparator procedurę acc. to PN-EN ISO 8503-2:2012

- Method for the calibration of ISO surface profile comparators and for the determination of surface profile — Stylus instrument procedurę acc. to PN-EN ISO 8503-4:2012

If you are interested in testing products related to metals and concrete - other than those listed above - then please contact us - we will try to meet your expectations.

Testing of coatings, hydrophobic impregnates and mortars applied to concrete substrates

Testing of hydrophobic coatings and impregnates:

In the field of testing products for concrete surface protection, we perform, among others.:

- test involving the assessment of the condition of the protective coating after a frost resistance test [200 cycles of freezing in air and thawing in water, at -18±2°C / +18±2°C] according to IBDiM Procedure No. PB/TM-1/13

- drying test for hydrophobic impregnation acc. to PN-EN 13579:2004

- water absorption and resistance to alkali for hydrophobic impregnations acc. to PN-EN 13580:2004

- thermal compatibility test after:

- thunder-shower cycling (thermal shock) acc. to PN-EN 13687-2:2008

- thermal cycling without de-icing salt impactwg acc. to PN-EN 13687-3:2002

- determination of liquid water permeability acc. to PN-EN 1062-3:2008

- measurement of bond strength by pull-off acc. to PN-EN 1542:2000

- determination of carbon dioxide permeabilitywg acc. to PN-EN 1062-6:2003

- determination of water-vapour transmission properties — Cup methodwg acc. to PN-EN ISO 7783:2018-11

- water absorption limitation test acc. to IBDiM Procedure No. PB-TM-X5

- abrasion test acc. to PN-EN 1338:2005

- roughness test acc. to PN-EN 1436:2018-02

- determination of crack bridging properties acc. to PN-EN 1062-7:2005

- determination of Graffiti Resistance acc. to ASTM D6578/D6578M-13(2018)

- determination of abrasion resistance — Part 1: Taber abrader acc. to PN-EN ISO 5470-1:2017-02

- determination of resistance to liquids — Part 1: Immersion in liquids other than water acc. to PN-EN ISO 2812-1:2018-01

Mortar and concrete testing

- determination of flexural and compressive strength of hardened mortar acc. to PN-EN 1015-11:2020-04

- determination of compressive strength of repair mortar acc. to PN-EN 12190:2000

- determination of shrinkage and expansion acc. to PN-EN 12617-4:2004

- determination of resistance of capillary absorption acc. to PN-EN 13057:2004

- frost resistance test of building mortars according to IBDiM research procedure No. PB/TM-1/12

- testing the thickness of concrete cover using a profometer as recommended by IBDiM

- test method for indicating moisture in concrete acc. to ASTM D4263-83(2018)

If you are interested in testing products related to metals and concrete - other than those listed above - then please contact us - we will try to meet your expectations.

Performing field tests

If you are interested in doing field research on metal and concrete related products - please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it. or This email address is being protected from spambots. You need JavaScript enabled to view it.

Inspectorate supervision

We carry out inspection [detailed and technological] supervision over the execution of coating corrosion protection of steel and reinforced concrete structures in the scope of steel and concrete surface evaluation:

- before applying coatings:

- determination of steel grades preparation

- determination of cleanliness preparation

- determination the roughness profile

- assessment of dust on steel surfaces

- determination of carbonation of concrete

- determination of concrete moisture

- determination of water-soluble salts

- determination of chloride content in concrete, etc.

- after applying coatings:

- determination of coating care class

- determination of coating thickness

- determination of adhesion of coatings

- assessment of porosity in a dry film

- gloss determination

- colour measurement

- determining the hardness of coatings, etc.

Exemplary supervision: Łazienkowski Bridge, Śląsko-Dąbrowski Bridge, Grota-Roweckiego Bridge, Siekierkowski Bridge (all in Warsaw, Poland), Bridge in Zakroczym, Bridge in Kiezmark, footbridges and noise barriers on the territory of the Capital City of Warsaw, capacitor in Bełchatów Power Plant, chimneys of Kozienice Power Plant.

Technical expertises

We perform expert opinions on the condition of structures in terms of threats and corrosion damage, the condition of anti-corrosion protection and the quality of paints and coatings (including expert opinions for the Court and expert opinions before renovations).

We can successfully, among other things:

- determine the properties of applied paints and carry out their identification

- assess the compliance of the construction of anti-corrosion protection system with the specification

- determine reasons for coating defects or corrosion occurrence

- verify the correctness of execution of field tests of coatings and execution of anti-corrosion works

Development and verification of documents

We develop and verify the projects of anti-corrosion protection of steel and concrete structures (new and renovated structures), Quality Assurance Programs (PZJ), Safety and Health Protection Plans BiOZ, technical terms of guarantee for anti-corrosion works in guarantee agreements, guidelines and recommendations of the public investor [Ministry, GDDKiA, ZDM, etc.] or private investor.

If you are interested, feel free to contact us.

Issuing of technical opinions on corrosion, painting systems, anti-corrosion coatings

We issue Technical Opinions on, among others:

- correctness of application of protective coatings on the structure

- the possibility of replacing anti-corrosion systems or changing elements of the anti-corrosion system designed to protect the surface of steel and reinforced concrete structures

- application of products working in particularly difficult conditions

- interpretation of applicable regulations and standards

Issuance of Technical Recommendations and National/European Technical Assessments

We prepare Technical Recommendations [RT] and National/European Technical Assessments [KOT/EOT] covering products for the protection of metal surfaces [protective coating systems] and concrete surfaces [filling mortars, rapid-setting mortars, repair mortars, impregnates, hydrophobic impregnates, protective coatings, anti-graffiti coatings, construction adhesives, insulation-surfacing, waterproofing, anti-humidity insulation, injection products, chemical anchors, etc.]. We prepare documents based on the performed tests.

Technical consulting on corrosion, corrosion problems, corrosion protection coatings

We advise and assist our customers in all areas covering the subject of corrosion, anti-corrosion coatings, all kinds of corrosion problems and corrosion documentation, among others, in:

- development of technical specifications in the field of anti-corrosion coating systems

- development of designs of anti-corrosion coating protections

- selection of technology before and during application of coatings

- selection of anticorrosion systems to protect structures in various environmental conditions [also in difficult / specific conditions]

- development and verification of Quality Assurance Programmes

- development of the Health and Safety Plan

- development of technical guarantee conditions in guarantee agreements for anti-corrosion works

Conducting R&D projects

We coordinate and perform research within research and development projects, both Polish and international.

We are open to cooperation and new research ideas.

Examples of R&D projects:

- "Evaluation of coating systems in field conditions on steel bridges using impedance technique" - KBN research project - 5 T07E 048 25

- "High impedance analyzer for anticorrosion coatings diagnostics" EUREKA HIADAC project Nr E!3174

- ARCHES Assessment and Rehabilitation of Central European Highway Structures - Smart-CP, Corrosion Monitoring

- Research and Development Project "Bridges in 3 months" under the Technological Initiatives of the Ministry of Science and Higher Education - Investigation of corrosion protection of reinforcement in concrete

- Projects with acronyms: DuraCoat ["Criteria and guidelines for evaluation and selection of anti-corrosive paint systems for steel structures"], ZincPower ["New generation of zinc primers with improved anti-corrosive, performance and environmental properties"], EcoWaterZinc ["Water, environmentally friendly high zinc pigmented primers"] - implemented within CORNET Initiative by partners from Poland and Germany - Polish Corrosion Society, Road and Bridge Research Institute, Łukasiewicz Research Network - Institute of Polymer Materials and Dyes Engineering - Paint and Plastics Branch in Gliwice, Forschungsgesellschaft für Pigmente und Lacke e. V. (FPL) and the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA). Projects funded by the National Centre for Research and Development (NCBR).

- Project with acronym DIAKO "Innovative, non-destructive diagnostics method of corrosion of reinforced concrete structures". - implemented under the INNOTECH project by a consortium consisting of: AGH University of Science and Technology, TPA Institute of Technical Research Sp. z o.o, Centrum Technologiczne BETOTECH Sp. z o.o., Instytut Badawczy Dróg i Mostów. Project financed by the National Centre for Research and Development.

Training in corrosion, surface preparation before coating, coating application, training in anti-corrosion standards, inspector training

We have been providing training in corrosion and corrosion protection for over 20 years.

Every year we organize:

- 3-stage course entitled. "Design and supervision of corrosion protection on steel structures". - The course of each level lasts 5 days and ends with an exam, and after a positive assessment a certificate is awarded. After completing the series of courses, a cumulative certificate with a 5-year validity period is issued

- 2-level course entitled. "Design and Supervision of Corrosion Protection on Concrete Structures". - the course of each level lasts 5 days and ends with an exam, and after obtaining a positive assessment, receiving a certificate. After completing the series of courses, a collective certificate with a 5-year validity period is issued

- a course extending the validity of certificates obtained after completion of the above training - the course extends the validity of certificates for another 5 years.

Moreover, we organise thematic seminars and workshops and we conduct individual training tailored to the needs of our customers, e.g. training in surface preparation before applying coatings or training in the proper selection of technology and application of coatings, practical training in the use of inspection equipment and training in standards, e.g. PN-EN ISO 12944 or PN-EN ISO 8501 or PN-EN ISO 8502.

If you are interested in conducting an individual training for your employees - please contact Ms. Urszula Paszek phone number: 600 457 498 or e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it..

EN

EN  PL

PL  DE

DE  FR

FR  IT

IT  ES

ES  CS

CS  SV-SE

SV-SE  DA

DA  NL

NL  HU

HU  RO

RO  UA

UA